TAMP-BLOW

APPLIES THE LABEL WITHOUT CONTACT ON MOVING OBJECTS

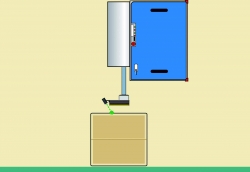

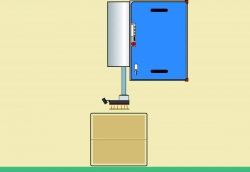

Linear movement applicator.

The tamp-blow applicator consists of a driven piston and a label-pick up pad by way of a vacuum generator and a sensor, which detects the actual pick-up of the label. The application occurs without contact with the object, by way of a powerful pulse of air.

The tamp-blow applicator consists of a driven piston and a label-pick up pad by way of a vacuum generator and a sensor, which detects the actual pick-up of the label. The application occurs without contact with the object, by way of a powerful pulse of air.

The tamp-blow applicator is commonly used for applying labels onto a stationary or moving object, also with a slightly irregular surface.

• In the case of surfaces with little adhesion it is better to use the finishing device of the application.

It consists of a soft rubber roll that presses the label as it passes (after labelling).

• Label dimensions: min. H 30 mm x B 30 mm (1.2" x 1.2"). max. H 120 mm x B 150 mm (4.7" x 5.9").

• In the case of surfaces with little adhesion it is better to use the finishing device of the application.

It consists of a soft rubber roll that presses the label as it passes (after labelling).

• Label dimensions: min. H 30 mm x B 30 mm (1.2" x 1.2"). max. H 120 mm x B 150 mm (4.7" x 5.9").

Models for different strokes:

• SHORT for a useful stroke of 300 mm. (11.8")

• LONG for a useful stroke of 600 mm. (23.6")

• SHORT for a useful stroke of 300 mm. (11.8")

• LONG for a useful stroke of 600 mm. (23.6")

Models for different application control:

• Model with an incorporated sensor that stops the stroke of the applicator piston in a precise position. It is suited to applying labels where the distance between the pack to be labeled and the printer is always the same. The pad in position awaits the passage of the package to blow the label.

• Self-adapting model with photocell positioned on the pad which detects the presence of the package during the application phase and then commands the piston to stop. This model is suited to applying labels where the distance between the pack to be labeled and the printer is not the same.

• Model with an incorporated sensor that stops the stroke of the applicator piston in a precise position. It is suited to applying labels where the distance between the pack to be labeled and the printer is always the same. The pad in position awaits the passage of the package to blow the label.

• Self-adapting model with photocell positioned on the pad which detects the presence of the package during the application phase and then commands the piston to stop. This model is suited to applying labels where the distance between the pack to be labeled and the printer is not the same.